Equipping Your Team for Lean Manufacturing

Maximize productivity. Minimize waste. Exceed line yield targets.

Deploy Lean Manufacturing From the Ground Up

Your team can make or break your lean program. Consistent procedure execution reduces variation and maintains continuity.

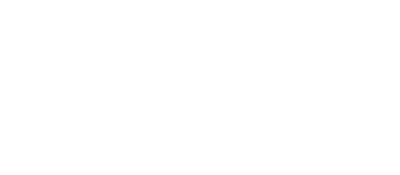

Our connected worker platform provides:

- Single source of truth for procedures and reaction plans

- Digital work instructions to ensure compliance

- Multi-media job aids to support accurate execution

- Training & capability tracking to Identify gaps in employee skills

Acadia makes it easy to execute lean manufacturing principles. See how one of our clients exceeded gross line yield goals in 6 months.

Lean Manufacturing Software that eliminates waste by supporting employees

Avoid defects and inventory issues by ensuring every employee executes consistently. Convert your procedures to digital work instructions and deliver them to employees at the point of use.

- Make troubleshooting procedures instantly available and easy to find

- Identify potential problems early by enabling front line communication

- Enable employees to identify process improvements during work

- Deploy process improvements without pausing for extensive training

- Measure individual compliance easily at scale

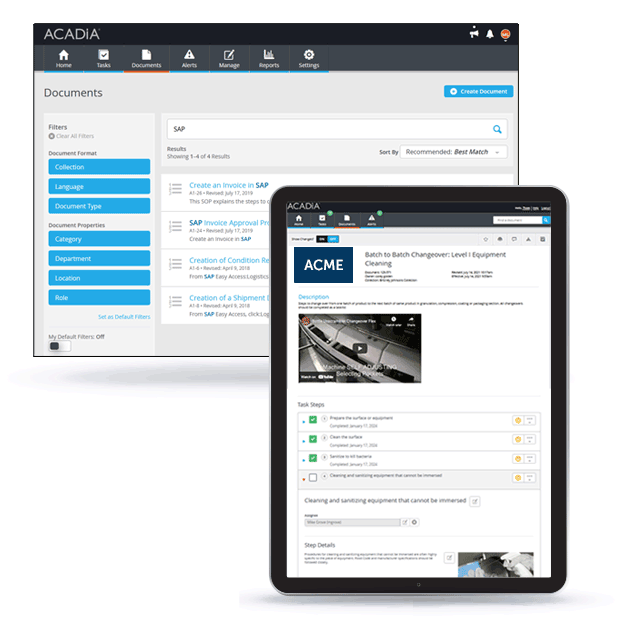

On-the-job training is more effective and sticks faster than classroom or shoulder-to-shoulder training.

- Guide training with step-by-step, role-based work instructions

- Provide support at the point of use with multi-media job aids

- Understand who’s doing well and who needs more support to be effective

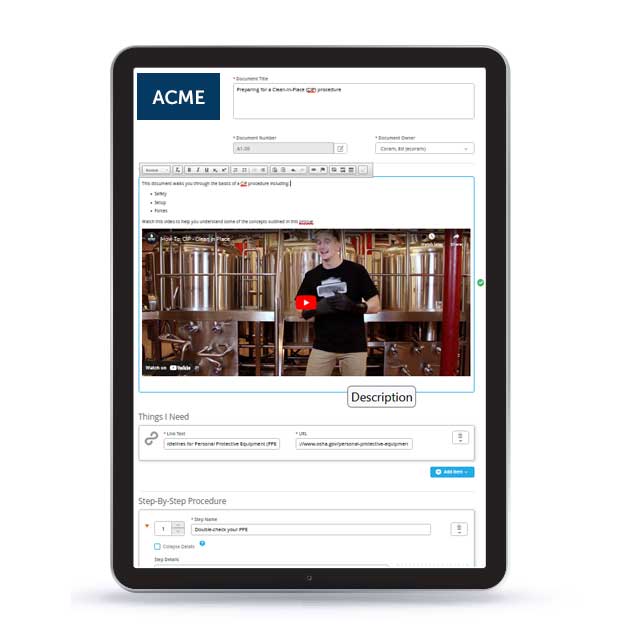

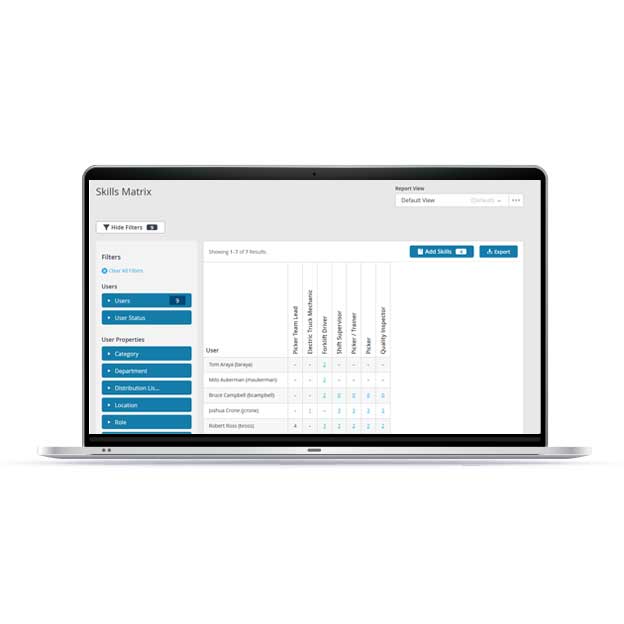

Understand your teams’ capabilities and where they have gaps. Then identify internal candidates most capable of filling them

- Combine daily activities and assessments to track employee capabilities

- Dynamically map those capabilities in a skills matrix

- Improve retention by providing more opportunity to your best performers

- Help each individual become better skilled with just-in-time access to information

Autonomous Production at a Global Scale at AB InBev

As one of the largest beverage and leading beer producers, AB InBev recognizes the importance of maintaining quality and consistency across their global production line. Since 2016, AB InBev has harnessed the power of Acadia to embrace lean manufacturing principles and foster autonomous teams.

To gain insight into how Acadia supports lean manufacturing at AB InBev, watch this brief video featuring Global Product Owner Denise Channer.

More Acadia Client Results

2 minute overview of Acadia

Acadia digital work instructions engage employees, quickly building competence and autonomy.

Watch this short video to see how it can help you drive results in your:

- Lean manufacturing program

- Continuous improvement projects

- Employee engagement & retention efforts

Let’s Talk Lean Manufacturing

"*" indicates required fields